RELATED PRODUCTS

DFX-7 Ultrasonic Flaw Detector

DFX-7 which is a product of DAKOTA ULTRASONIC is an ultrasonic flaw detector, as well as a high-precision thickness measuring device with A and B scanning features.

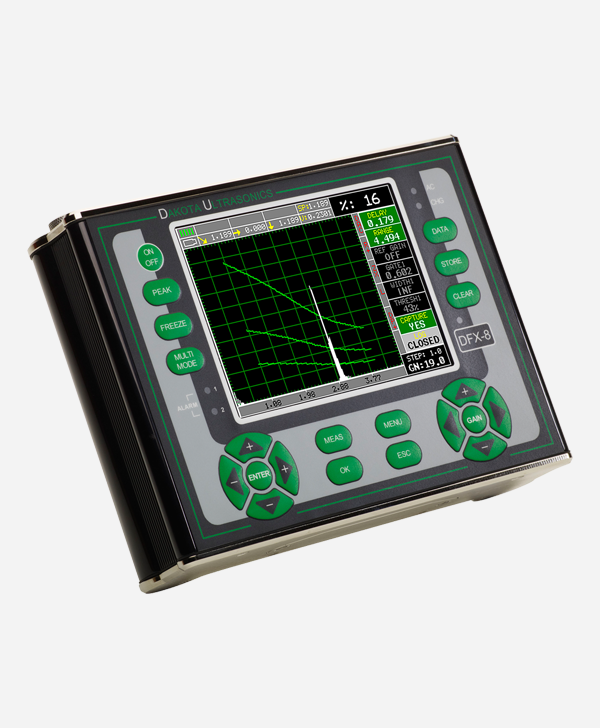

İNCELEDFX-8 Ultrasonic Flaw Detector & Thickness Gauge

Dakota DFX-8 allows you to perform your Ultrasonic Inspection efficiently in any environment with its QVGA Blanview screen that can be seen even under sunlight.

İNCELEDC 2000 Ultrasonic Thickness Gauge

DC 2000 Ultrasonic Thickness Gauge is used to measure the thickness of various materials such as steel, stainless steel, aluminium, copper, composite, plastic, glass, polyethene without coating or paint on the surface.

İNCELEDC 3000 Ultrasonic Thickness Gauge

DC 3000 Ultrasonic Thickness Gauge is used to measure the thickness of various materials such as steel, stainless steel, aluminium, copper, composite, plastic, glass, polyethene with/without coating or paint on the surface.

İNCELEDC 4000 Ultrasonic Thickness Gauge

DC 4000 Ultrasonic Thickness Gauge works with Pulse-Echo and Echo-Echo measurement methods.

İNCELE