OVERVIEW

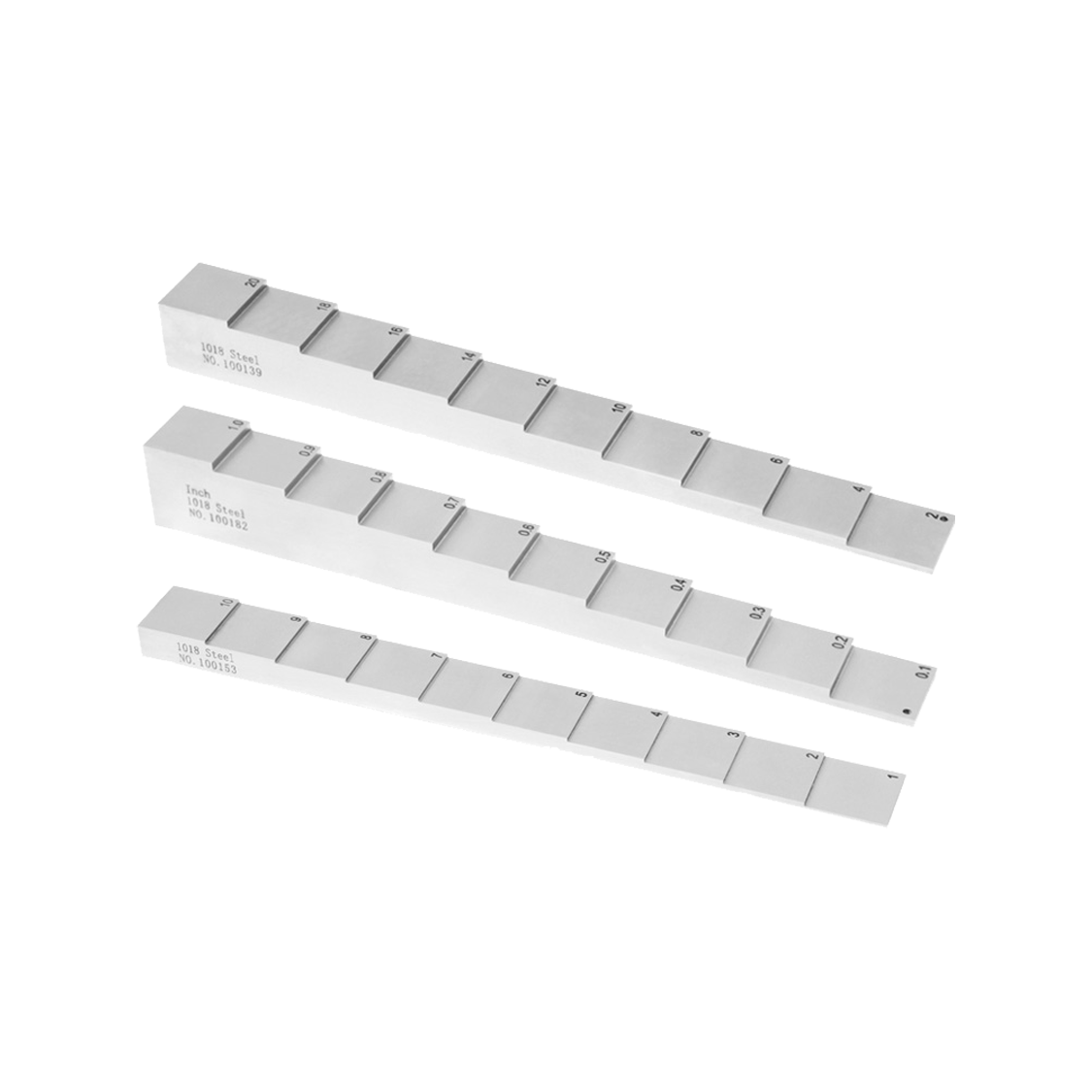

Calibration blocks are used to calibrate the sound velocity of the probe. Generally, K1 (V1), K2 (V2), DAC, and stepped calibration blocks used in the Ultrasonic Inspection method are provided in accordance with standards with different production material options (Carbon steel, Aluminum, Stainless steel).