WHAT IS THE PENETRANT TESTING?

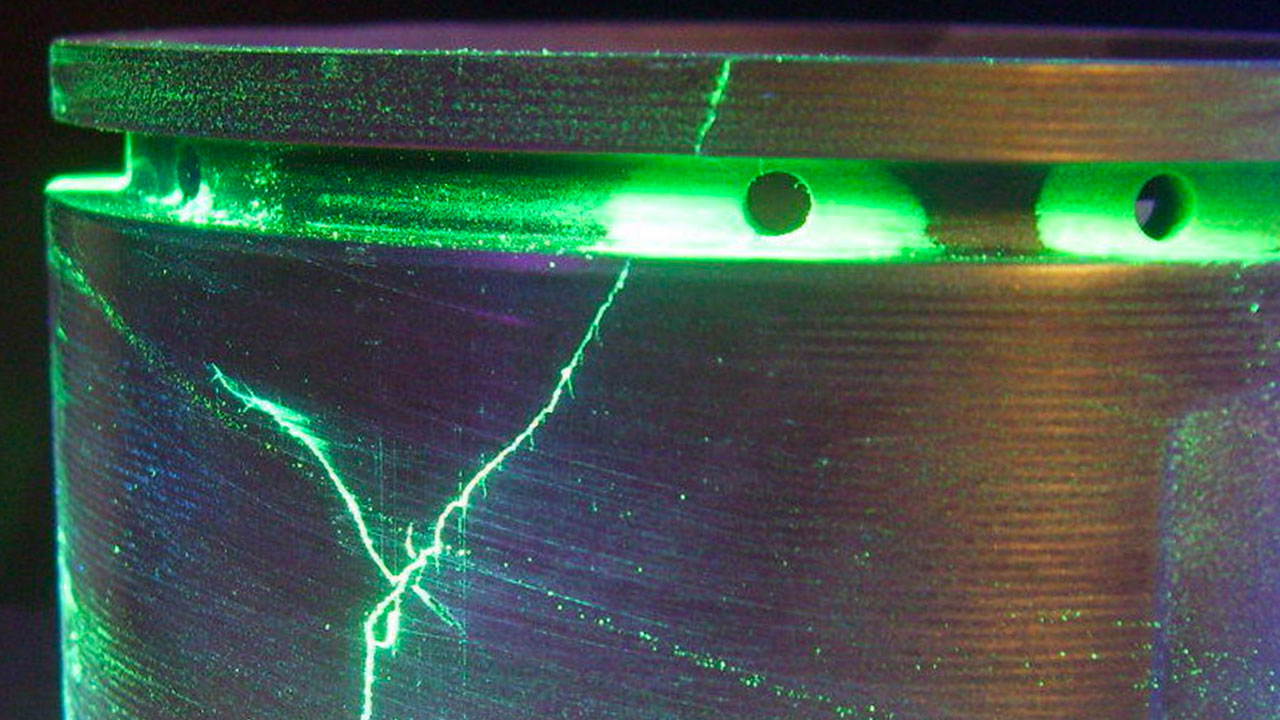

Penetrant or Liquid Penetration is a non-destructive testing (NDT) method used to detect defects on the materials’ surface. Penetrant testing can be applied to all metals, ceramics, glass, and plastic materials.

The most important point to be considered in the Penetrant

Testing method (LPI, DPI, PT) is that the discontinuities on the surface to be

examined must be open to the surface. Otherwise, discontinuity detection cannot

be made. With the penetrant test, discontinuities such as fatigue cracks,

quenching cracks, pores, surface defects due to machining are detected.

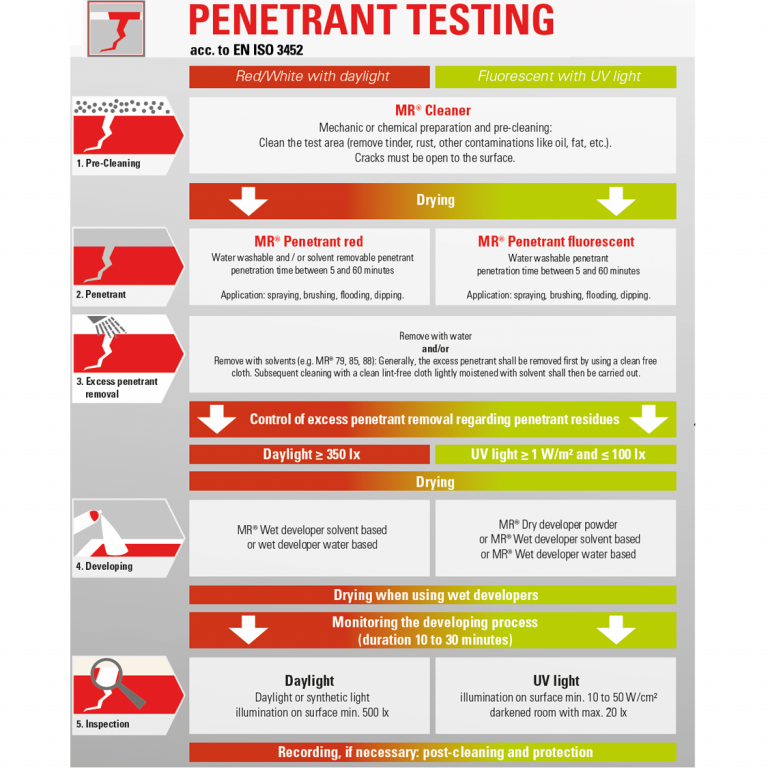

Penetrant Test generally consists of 4 stages. These stages

are listed as follows.

1. Pre-cleaning: Cleaning the surface to be inspected before

penetrant treatment

2. Penetrant: Application of the penetrant

3. Excess Penetrant Removal: Cleaning the penetrant on the

material surface

4. Developer: Bleeding out the penetrant penetrating into

the discontinuity to the surface with the help of the developer

After these stages, the material is visually inspected and

the discontinuities detected are reported.

Advantages of the method;

- It can be applied to almost all materials.

- Costs are lower.

- Results can be obtained in a short time.

- It provides high sensitivity in the detection of

discontinuities open to the surface.

Disadvantages of the

Method;

- Only discontinuities open to the surface can be detected.

- It is difficult to apply on materials with a porous

surface.

- Pre-cleaning is of great importance.

- Test material should be cleaned after inspection.